How to Choose the Right PV Cables for Your Solar Energy System?

Choosing the right PV cables for your solar energy system can significantly impact performance and longevity. According to Dr. Emily Carter, a leading expert in solar technology, "Selecting quality PV cables is essential for the efficiency of solar installations." The right cables ensure energy transmission is optimized, reducing losses and enhancing system reliability.

When considering PV cables, factors such as temperature ratings, insulation materials, and environmental conditions are vital. For instance, cables exposed to extreme weather require robust protective features. Many installers overlook these details, which can lead to inefficiencies. Understanding the specifics of your installation helps to make an informed decision.

Moreover, the market offers various specifications and types of PV cables. Navigating these options can be daunting. You might feel tempted to cut costs by choosing cheaper alternatives. However, this can lead to greater expenses in maintenance and replacements later on. Identifying the right balance between cost and quality is crucial for sustainable solar energy systems.

Understanding the Basics of PV Cables in Solar Energy Systems

When setting up a solar energy system, PV cables play a crucial role. These cables connect solar panels to inverters and batteries. Choosing the right type is essential to ensure efficiency and safety. PV cables must withstand harsh weather conditions. They need to be durable and resistant to UV rays. The right insulation material is critical for longevity.

There are different types of PV cables available. Some offer higher current ratings and lower resistance. However, not all cables are created equal. It’s important to choose a size that matches your system’s needs. Often, users overlook the importance of proper gauge cables, leading to power losses. Using cables that are too thin can create overheating issues.

Consider the installation environment. Cables used indoors may differ from those exposed to outdoor elements. Pay attention to the temperature rating as well. In some areas, extreme heat or cold can affect cable performance. Make sure you have a backup plan if things don’t go as expected. Solar power can be reliable, but your cable choice can make a significant difference.

Key Specifications to Consider When Selecting PV Cables

Selecting the right photovoltaic (PV) cables is crucial for the efficiency and longevity of solar energy systems. Key specifications to consider include temperature ratings, voltage ratings, and insulation types. According to a report from the National Renewable Energy Laboratory, cables must endure varied environmental conditions. This includes high temperatures, UV exposure, and moisture. The cables should support a temperature range from -40°C to 90°C for optimal performance.

Another important aspect is the voltage rating. Many solar systems operate at voltages up to 1,000 V DC, while some specifications can go as high as 1,500 V DC. Choosing cables with a matching voltage rating ensures safety and efficiency. Additionally, conductors made from copper or aluminum offer different advantages. Copper has better conductivity but can be pricier. Aluminum is lighter and more cost-effective but might require larger diameters for the same conductivity.

Lastly, insulation materials like XLPE or PVC are critical. XLPE provides better resistance to heat and chemicals. Yet, it may have a higher upfront cost. Regular assessments can reveal decay or damage. It’s important to regularly check cable conditions to avoid failures that can lead to significant power loss.

How to Choose the Right PV Cables for Your Solar Energy System?

| Specification | Description | Importance |

|---|---|---|

| Cable Type | Solar PV cables come in different types, such as PV1-F and H1Z2Z2-K | Determines compatibility with solar installations and environment. |

| Voltage Rating | Indicates the maximum voltage the cable can handle (typically 600V or 1,000V). | Ensures safety and efficiency in power transmission. |

| Temperature Rating | Cables should operate in a temperature range (often -40°C to +90°C). | Important for durability and performance in extreme conditions. |

| Conductor Material | Commonly made from copper or aluminum. | Affects conductivity and overall efficiency. |

| Sheathing Material | Typically made from thermoplastic or thermoset materials. | Provides protection against environmental factors and UV exposure. |

| Length | Available in various lengths; should be calculated based on installation. | Important for reducing potential power loss. |

| Certification | Check for local and international certifications (e.g., TUV, UL). | Ensures compliance with safety and performance standards. |

Comparing Different Types of PV Cables for Solar Installations

When it comes to selecting PV cables for solar installations, various types cater to different needs. For instance, silicone insulated cables are notable for their flexibility and durability. They can withstand extreme temperatures and harsh environmental conditions. According to a report by the National Renewable Energy Laboratory, these cables can last up to 25 years in outdoor applications. However, they can be more expensive than traditional cables, which might deter some customers.

On the other hand, PVC insulated cables are quite popular due to their cost-effectiveness. They are generally easier to install and more affordable. However, they may not perform as well under extreme conditions. The International Electrotechnical Commission notes that while PVC cables are rated for a lifespan of 20 years, exposure to UV light can lead to premature degradation. This contrast in performance raises concerns about longevity and reliability.

It's crucial to consider these factors. Are you working in a region with severe weather? Do you prioritize upfront costs or long-term reliability? Many installers make choices based on short-term needs, but often overlook future implications. A poor choice now can lead to increased maintenance costs later. Always reflect on the long-term performance of the cables you select for your solar energy system.

Evaluating Environmental Factors Affecting PV Cable Performance

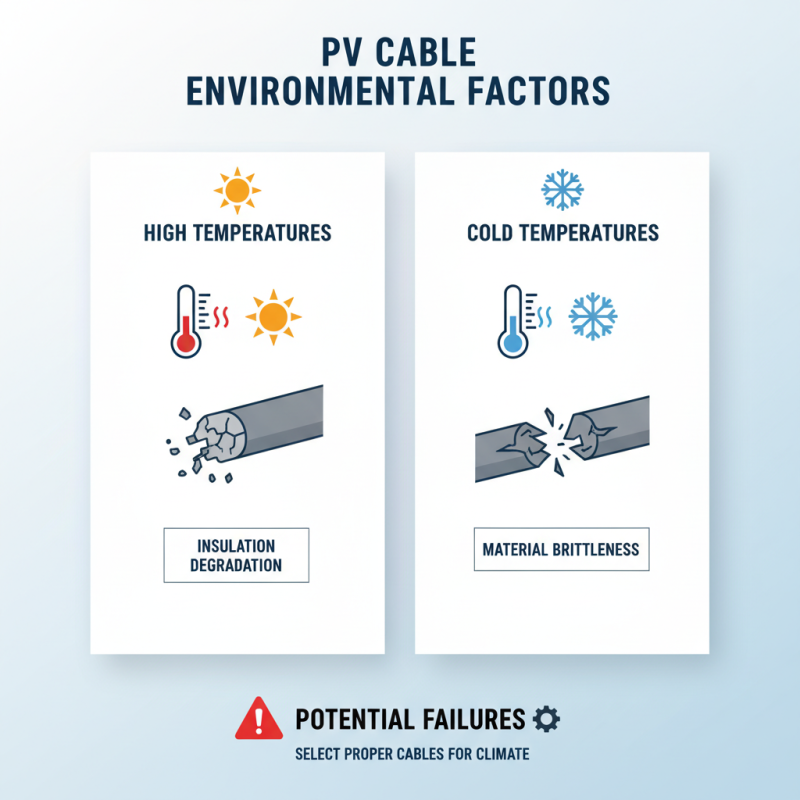

When selecting PV cables, environmental factors play a crucial role. Temperature variations can significantly affect cable performance. High temperatures may cause insulation degradation. In contrast, colder conditions can make materials brittle, leading to potential failures.

Humidity is another important consideration. High moisture levels can lead to corrosion and short circuits. Ensure your cables are resistant to water ingress. This protection can extend the lifespan of your system.

Tips: Check local weather patterns. Evaluate the average temperature ranges before installation. Consider using UV-resistant cables if exposed to sunlight. These small choices prevent bigger issues down the line.

The installation environment matters too. Dust and debris can accumulate, affecting performance. Use protective conduits in dusty areas. Additionally, regular maintenance checks are essential. They help identify wear early and prevent serious damage.

Installation Tips for Ensuring Optimal PV Cable Functionality

When planning a solar energy system, the installation of PV cables is crucial. Proper installation minimizes energy loss and maximizes system performance. Data from industry reports indicate that improper cable connections can reduce efficiency by up to 20%. Choosing cables that meet local electrical codes is essential. Understanding voltage ratings and temperature limits helps ensure safety and longevity.

Careful placement of cables prevents wear and tear. Avoiding sharp bends protects the integrity of the cables. Use protective conduits when installing cables outdoors. The National Renewable Energy Laboratory states that exposed cables can degrade over time due to UV exposure. Regular inspections for signs of damage are vital. Issues like frayed insulations can lead to significant problems.

Labeling cables clearly helps identify their function and prevents mishandling. Yet, many installations overlook this step. Ensuring proper separation between AC and DC cables reduces electromagnetic interference. This can be a common oversight, yet it impacts system efficiency. Investing effort in these small details can yield substantial long-term benefits.